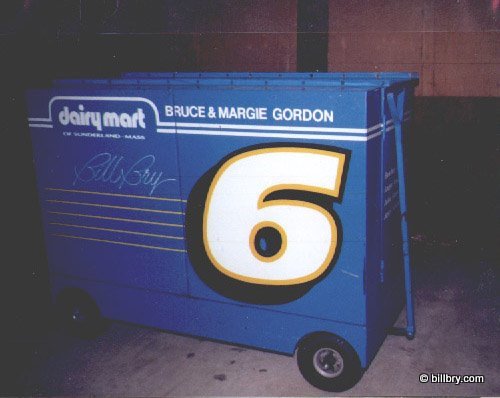

Bill Bry: The Father of the Live Free and Build duo, with 40 years working in the field, is a master of his trade and is an excellent choice for your project! Through a wide variety of work experience he has worked in nearly every aspect of the welding fab trade, structural, automotive, agricultural, industrial, food service. Bills customers always love his quality work, almost as much as they love his problem solving ability, being called “MacGyver” by his customers on many occasions when he performed emergency repairs against all odds. In addition to being a lifelong welder, Bill is also an automotive enthusiast and accomplished Nascar racer with 3 Pro Stock championships in a row. This Nascar experience is incredibly valuable, as it means you can build a car, a tool setup, and a team that can make it to the track both on time and competitive for 20 weekends in a row.

Kyle Bry: As the son of a self employed welder, you have the opportunity to get involved earlier than most do. Kyle did his first welding project at 7 years old, and completed a number of other projects throughout childhood until enrolling in a technical high school to start a more formal 4 year trade education. By the end of freshman year Kyle had already learned advanced processes like arc welding and aluminum TIG. He spent sophomore year doing customer jobs for the school, then most of junior and senior practicing for various tests and certifications in various welding processes. In 2017 he won first place against 121 competitors from 19 schools in the Notch Mechanical Constructors pipe welding challenge. After high school, living in rural western Massachusetts didn’t have much welding work, and he didn’t want to move to one of the near cities. This led him to get a job at a family friend’s tree service. Over 4 years at this job he became second in command and learned to handle all daily tasks of running a tree crew with an emphasis on the equipment operation/maintenance. Over this time on the tree crew he also completed hundreds if not thousands of hours doing welding and equipment repair on the side.